Q1.Are you a manufacturer or a trading company?

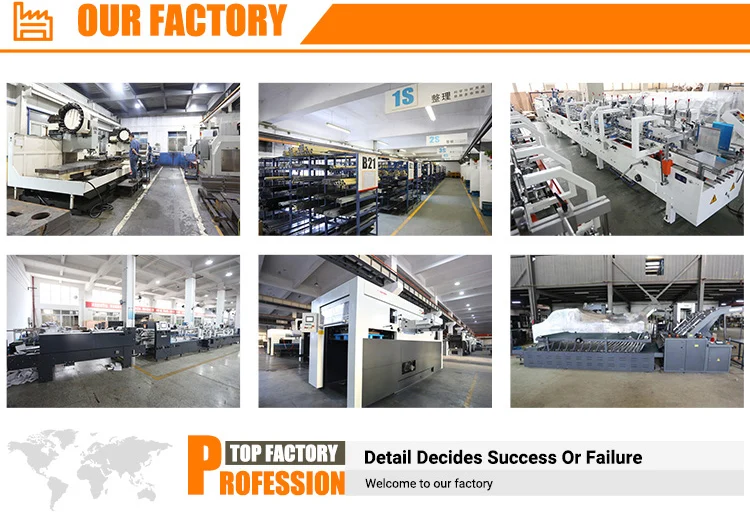

A:Our shanghai office is mainly doing export.We have our own factory in Wenzhou,Zhejiang Province.

Q2.What is the machine warranty?

A:One year.After the warranty,we still provide technical support to buyer at low cost.

Q3.What is the production time while placing order?

A:Normally about 10-20 days.

Q4.What is the delivery time?

A:15-30days after deposit.

Q5.Can your company handle shipping for customers?

A:Yes,just give us destination sea port or container yard.

Q6.Does the packing strong?

A:Yes.Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions.A full set of maintenance and operation manuals is included.

Q7.How about the machine installation and training?

A:1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for installation and training.You shall pay the round trip air fare and accommodations,plus each technician charges USD100/per day.

Q8.Do you have machines in stock?

A:For standard model,we have a large quantity in stock.For special model,we need 20-30 days to produce it for you.

Q9.How can you assure the machines’ quality?

A:Each machine will be test running at least 24 hours before delivery to assure the quality.

And during the warranty,we will give spare parts for free if machine has any problem.

Q10.Do you inspect machines or test running before packing?

A:Of course we do.We have QC department to debug the machine before packing.

If you want to use specific material to do the test running,you need to pay for the cost of the material.

Q11.What’s the payment term?

A:T/T 30% in advance,the balance shall be paid before delivery.We also accept payment by West Union or L/C at sight.

Q12.Do you accept factory visiting?

A:Warmly welcome for your visiting.

Q13.How many years are you in printing field?

A:The Shanghai company since in 2008,the factory is more than 25years.

Q14.How many clients do you have?

A:We have sold our machines to about 60 countries.We have agents in South Africa,Morocco and Italy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!