| Place of Origin: | China |

|---|---|

| Brand Name: | PRINTYOUNG |

| Certification: | CE |

| Model Number: | ZKT-890A , ZKT-1200A |

| Minimum Order Quantity: | 1 Set |

| Price: | US 50000 - 65000 Set |

| Packaging Details: | Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions. A full set of maintenance and operation manuals is included. |

| Delivery Time: | 30 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Set/Sets per Month |

| Product Type: | Window Patching Machine | Voltage: | 380 V |

|---|---|---|---|

| Power: | 19.5 Kw , 22kw | Dimension: | 6500 * 1650 * 1950 Mm , 6500 * 1500 * 1800 Mm |

| Weight: | 2300 Kg , 3500 Kg | Production Capacity: | 4000-13000 Pcs/h , 5000-13000 Pcs/h |

| Paper Length: | 120 - 780 Mm | Paper Width: | 140 - 800 Mm , 120 - 1100 Mm |

| Film Length: | 60 - 400 Mm | Film Width: | 40 - 450 Mm , 30 - 500 Mm |

| Pump Power: | 4.5 Kw , 1.5 Kw | ||

| High Light: | Automatic Envelope Pasting Machine,Envelope Pasting Window Patcher Machine,Envelope Window Patching Machine 380V |

||

|

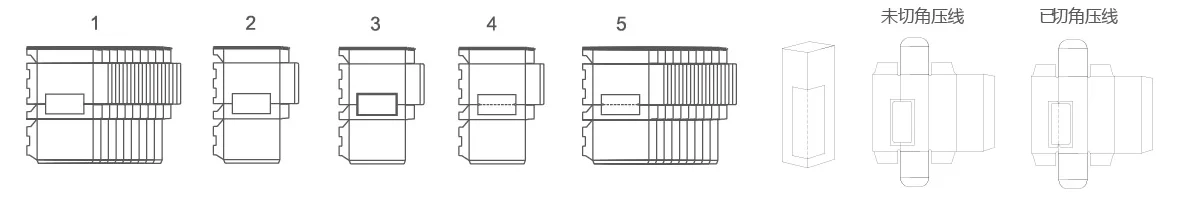

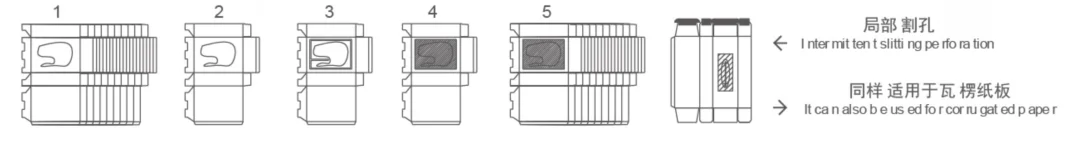

ZKT-A Series Window Patching Machine

|

||

|---|---|---|

| Model | ZKT-890A | ZKT-1200A |

|

Paper Length

|

120 - 780 mm

|

120 - 780 mm |

|

Paper Width

|

140 - 800 mm

|

120 - 1100 mm |

|

Film Length

|

60 - 400 mm

|

60 - 400 mm |

|

Film Width

|

40 - 450 mm

|

30 - 500 mm |

|

Paper Caliper

|

paper box & cardboard box 250-1000 g/m2,

corrugated/flute up to 3 mm |

paper box & cardboard box 250-1000 g/m2, corrugated/flute up to 3 mm |

|

Film Thickness

|

0.05 - 0.25 mm,OPP,PVC,PET,PE etc

|

0.05 - 0.25 mm,OPP,PVC,PET,PE etc |

|

Speed

|

4000-13000 pcs/h (Normal Pasting)

4000-12000 pcs/h (Corner cut & Creasing) |

5000-10000 pcs/h (Normal Pasting) 5000-13000 pcs/h (Corner cut & Creasing) |

|

Pump Power

|

4.5 kw

|

1.5 kw |

|

Machine Power

|

19.5 kw

|

22 kw |

|

Machine Weight

|

2300 kg

|

3500 kg |

|

External Dimension

|

6500 * 1650 * 1950 mm

|

6500 * 1500 * 1800 mm |